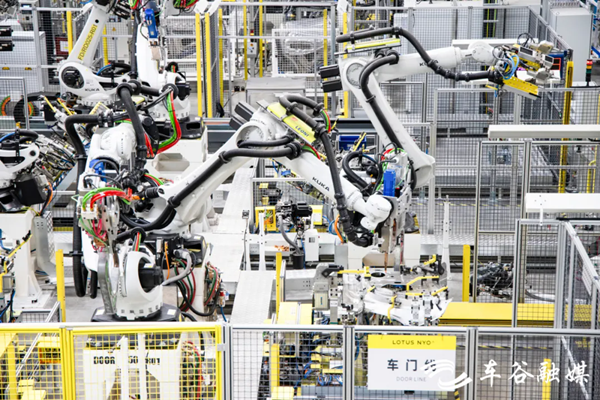

The interior of the Lotus NYO Global Smart Factory in the Wuhan Economic & Technological Development Zone. [Photo/WeChat account: whkfq]

The Ministry of Industry and Information Technology recently announced the "2024 5G Factory Directory", featuring the country's top 400 5G factory projects.

Among those selected was the Lotus NYO Global Smart Factory in the Wuhan Economic & Technological Development Zone (WEDZ). It is the only 5G automotive manufacturing factory in Wuhan to be included and the second national-level 5G factory in WEDZ.

The factory is the world's first to use 3D digital twin technology throughout its planning, design, and construction process. It boasts an overall intelligence coverage rate of 95 percent, achieving comprehensive flexibility from order to delivery, making customized cars a reality.

"The virtual digital factory and the real factory are like twins," explained a factory representative. The factory can simulate the assembly, installation, and debugging of equipment online through digital twin technology, significantly improving construction efficiency. Once built, the digital factory synchronizes the entire production process from a steel plate to a complete vehicle. Engineers can experiment with improvements on the "twin", enhancing efficiency and reducing costs.

A single production line in the nearby welding workshop supports an annual capacity of 150,000 vehicles and customized production. After producing one car, the line can immediately adjust parameters and molds to seamlessly switch to another model, outputting up to 96 configurations.

The workshop is equipped with 143 robots and 22 visual assistance systems. It uses 16 connection processes to create high-strength, lightweight car bodies. This setup supports the steel-aluminum mixed production capability and realizes full-process intelligence and digitization.

"The application of 'data and intelligence' has maximized the flexible production of the factory, unleashed powerful 'intelligent manufacturing' capabilities, and achieved an output value of over 10 billion yuan ($1.38 billion) last year," stated a factory representative.

In recent years, WEDZ has been ramping up efforts to accelerate its industrial digital transformation around "5G+ intelligent manufacturing". It has nurtured four fully connected 5G factories, including Midea HVAC and Lotus NYO, and three national-level intelligent manufacturing demonstration factories, including Voyah Automobile.

The zone has developed 83 digital production lines, 30 intelligent demonstration workshops, and seven benchmark intelligent factories.