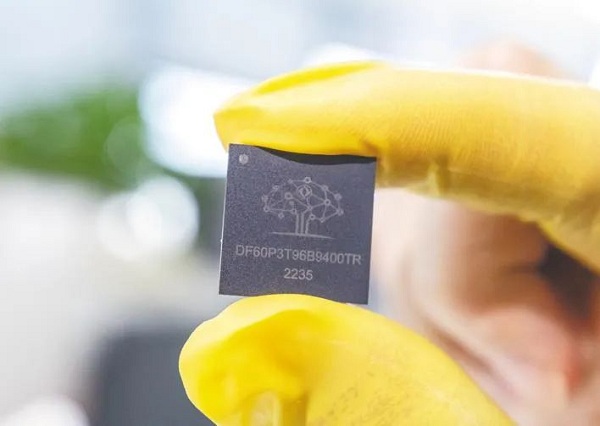

The micro control unit (MCU) chip for vehicles is produced in Central China's Hubei province. [Photo provided to en.whkfq.gov.cn]

The micro control unit (MCU) chip for vehicles produced in Hubei province recently achieved Automotive Safety Integration Level-D (ASIL-D) certification, the highest-level functional safety system certification in the automotive industry.

This certification means that the MCU chips have a complete functional safety and development system. This type of chip is expected to become the first domestically produced ASIL-D chip that will enter mass production in China.

According to Cai Min, vice general manager of Wuhan Binary Semiconductor Co, this chip will be applied in various automotive domain controllers, such as automobile engines and gearboxes.

The chips will be manufactured, packaged and tested by domestic manufacturers, all of which are companies affiliated with the Hubei Technology Innovation Consortium for the Automotive-grade Chip Industry.

The front-end and back-end design of a chip typically takes one to three years, and the development period for automotive-grade chips is even longer, requiring three to five years from development to mass production.

In order to address the bottleneck issue in automotive chip development, an innovation consortium was established in 2022, with Dongfeng Motor, based in the Wuhan Economic & Technological Development Zone (WEDZ), and eight other enterprises and institutions, jointly established the innovation consortium.

"The mass production of this chip is expected to be achieved next year," said Cai. For the innovation consortium, however, the focus is not only on successfully developing automotive-grade chips, but also on improving the entire domestic production ecosystem.