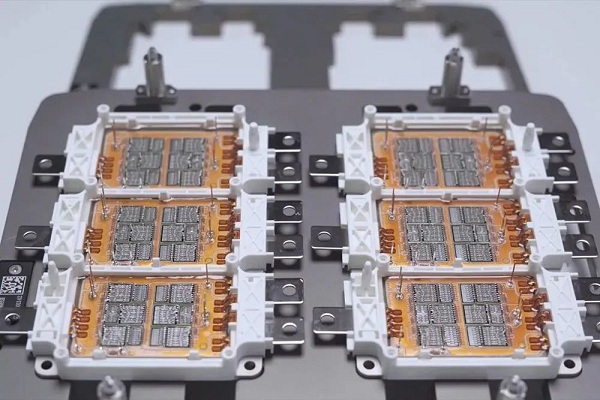

The IGBT module produced by Zhixin. [Photo provided to en.whkfq.gov.cn]

In the module sealing factory of Zhixin Semiconductor Co, the insulated gate bipolar transistor (IGBT) production line never stops working and is monitored by fewer than 20 operators through a computer screen.

"The demand for new energy vehicles (NEV) is rising, and all our IGBT modules have been sold out. Now we are in production overdrive to keep up with demand," said Wang Min, an engineer from Zhixin's R&D department.

IGBT has been hailed as the "heart" of NEVs, in that its performance will directly determine the cars' torque and nominal power. Due to a lack of core technologies, about 95 percent of IGBT modules in China were imported from overseas.

For this reason, Dongfeng Motor and CRRC founded Zhixin in 2019, and began developing independent automobile chips.

Last year, the sixth-generation IGBT production line made its debut in Wuhan Economic & Technological Development Zone (WEDZ), becoming the first of its kind in Central China capable of designing, manufacturing, sealing, and testing IGBTs.

The production line is highly automated, with only a team of eight workers able to manage more than 40 machines. The first group of IGBT modules to roll off the line has been used in Dongfeng models such as VOYAH and AEOLUS.