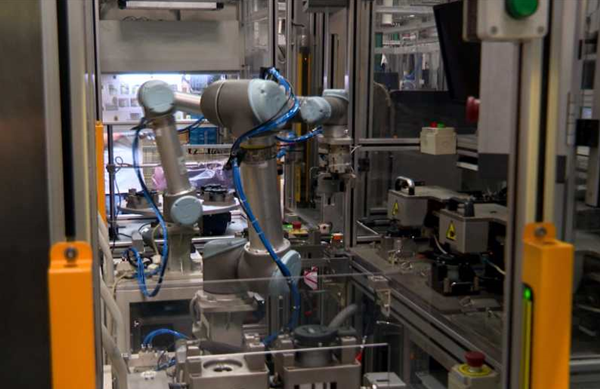

Cutting-edge automated production equipment swings into action at the Dongfeng Brose Automotive Systems Co plant in the WHDZ. [Photo/whkfq.gov.cn]

High-tech pioneer Dongfeng Brose Automotive Systems Co has been promoting intelligent manufacturing, so as to reduce business costs and improve production efficiency, according to local media reports.

Located in the Wuhan Economic & Technological Development Zone (WHDZ) -- in Wuhan city in Central China’s Hubei province -- Dongfeng Brose Automotive Systems Co is a Sino-German joint venture auto parts company.

Since 2016, the company has gradually implemented the intelligent transformation of its automated production line, traceability systems and power facilities.

With the introduction of intelligent manufacturing, one of the gearbox motor production lines has reduced its workforce from the original team of 11 to five workers.

A company spokesman said the production line capacity at the same time has increased from 190 units per person per shift to 420, bringing direct economic benefits of some 1.6 million yuan ($228,960) per year.

According to company officials, since its establishment, the company has invested about 30 to 50 million yuan in intelligent manufacturing. Through its continuous transformation in recent years, the annual cost savings have topped 2 million yuan.

At present, a total of five companies in the WHDZ -- including Gree Electric Appliances and Chassis Brakes International (Wuhan) Co -- have been given the appellation of a Wuhan Intelligent Renovation Demonstration Project.

In addition, 12 companies including Dongfeng Mahle Thermal System Co and Wuhan Fanzhou Chuetsu Metal Co have received subsidies for the Wuhan Intelligent Renovation Project.

In 2019, a total of 76 enterprises in WHDZ completed the intelligent diagnoses and evaluations, ranking the WHDZ first among all districts and zones in the city.